Electric motorized water control valve YS20S, 2 wires actuator 95-250 VAC Normally Closed

$ 240.00

DESCRIPTION Ideal replacement for a solenoid valve that fails frequently, specially in cooling blowdown applications. Motorized water control valve with electronic return to close when power is removed. This is not...

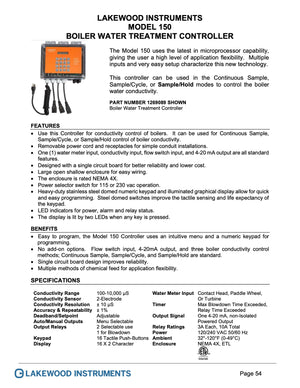

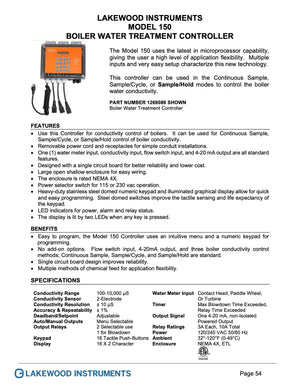

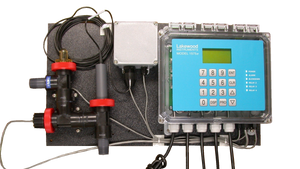

Boiler water TDS, controller Lakewood model 150

$ 2,033.00

DESCRIPTION The boiler water TDS controller model 150 use the latest in microprocessor capability, giving the user a high level of application flexibility. Multiple inputs and very easy setup characterize this...

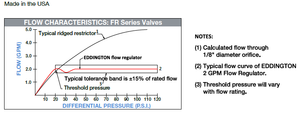

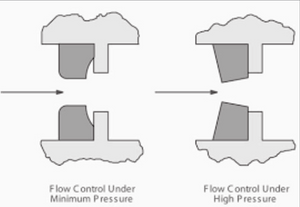

Inline water flow regulator Brass 1.0 to 30 GPM (Dole valve)

$ 71.00 $ 95.00

DESCRIPTION The Inline Water Flow Regulator (Dole valve) is designed to deliver a constant volume of water flow over a wide pressure drop range. The constant flow of water is maintained...

Water electrical conductivity controller for cooling towers Lakewood model 140

$ 923.00

DESCRIPTION Instant Discount once added to the Cart! The water electrical conductivity controller for cooling towers should be simple and easy to operate. The key parameter to control is the concentration of dissolved...

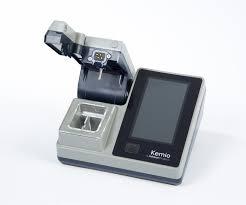

KEMS10HM Kemio Heavy Metals, Soft Case Kit

$ 3,223.00 $ 3,700.00

DESCRIPTION Please request a quote at sales@yamathosupply.com Protect against lead and cadmium contamination with Kemio Heavy Metals. Kemio is the next generation measurement platform, delivering repeatable and reliable results to...

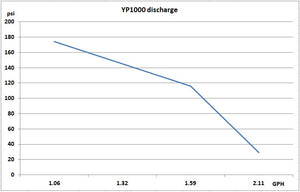

Chemical injection diaphragm pump Seko APG 603 1GPH max @ 175 psi with PVDF liquid end ( APG603 )

$ 315.00 $ 399.00

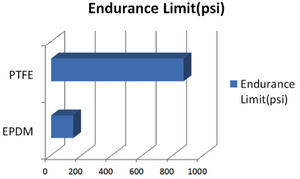

Simplify Wet Materials: EPDM, PTFE and PVDF (Check compatibility here!) What is this? Max Pressure: 175 psi What is this? Max Flow Rate: Adj. from 0 to 1 GPH (@ 174 psi) What is this? Power: 110 VAC and...

Boiler blowdown, water TDS controller Lakewood Instruments model 1575e. Select add on options from dropdown list

$ 1,289.00

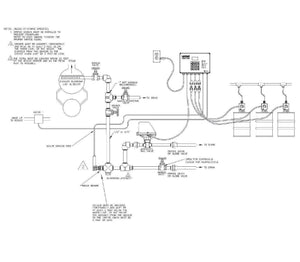

Boiler water TDS controller, designed to measure the hot boiler water conductivity (sensor SR2) and open or close a motorized ball valve, that will drain water from the boiler. The automatic...

Lakewood 1575e p/n 1229239 Water Cooling Tower Controller. Select add ons from dropdown list.

$ 999.00 $ 1,450.00

Cooling tower water treatment control is simple and an automatic system will allow the tower to operate at the maximum allowed water concentration, reducing the usage of chemicals and fresh...

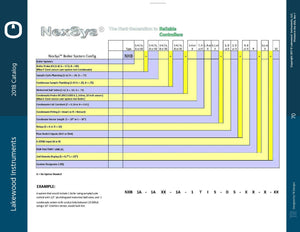

NexSys Boiler Controller (NXB). Select add-on from drop downs

$ 4,483.00

DESCRIPTION Use code CCFTWZV2NJG3 for an instant 15% discount on checkout! The Model 150 uses the latest in microprocessor capability, giving the user a high level of application flexibility. Multiple inputs...

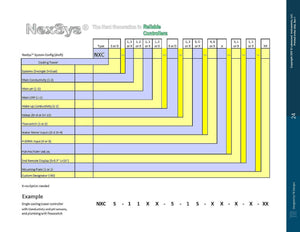

NexSys Water Cooling Tower Controller only, p/n NXC. Please select model from Dropdown list!

$ 4,824.00

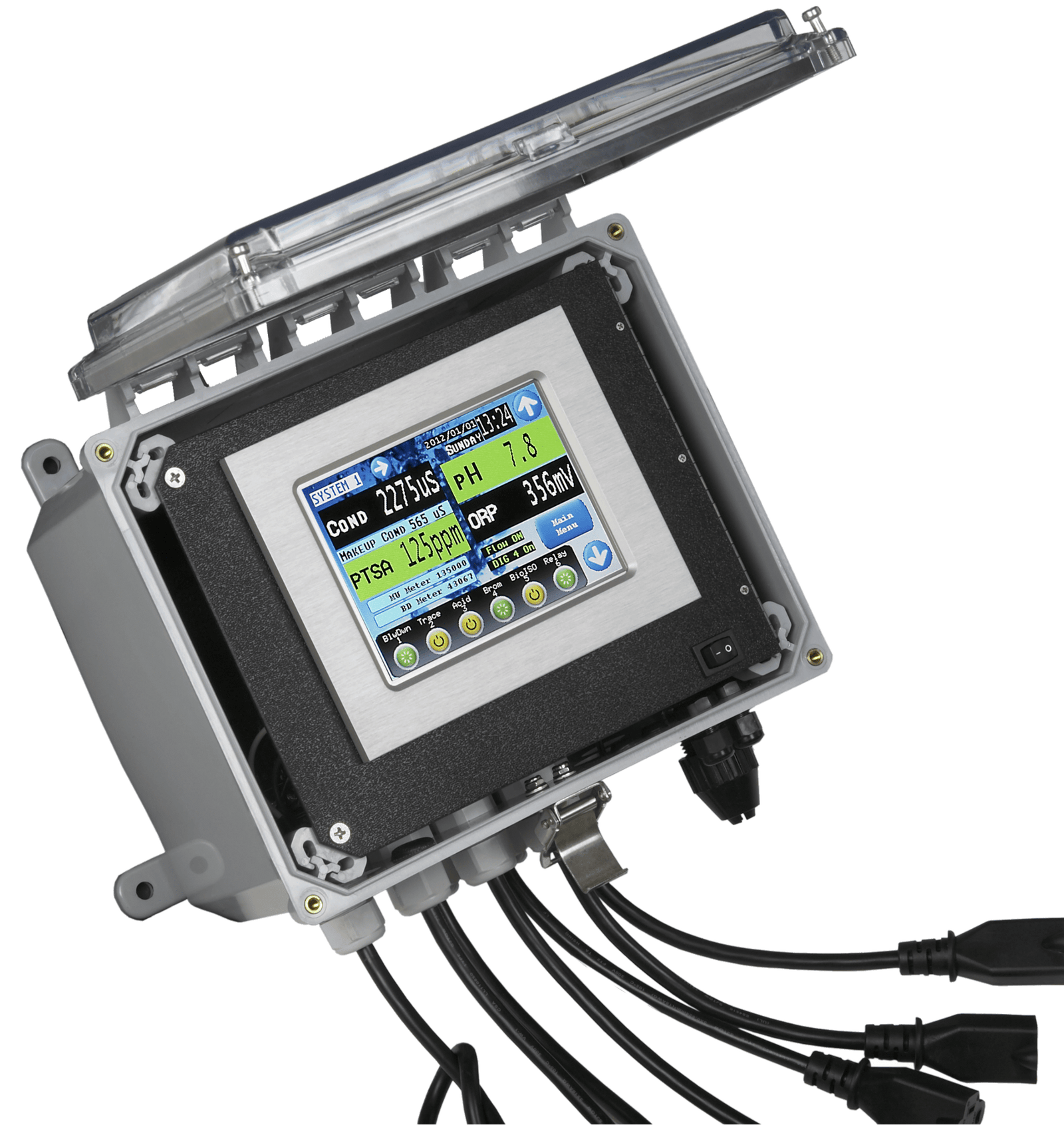

Description The NexSys® water cooling tower controller is the latest in a long line of reliable, easy to use controllers from Lakewood Instruments. The NexSys® control system uses the latest in microprocessor technology with...

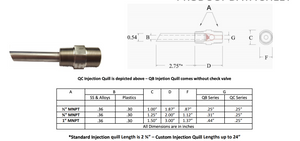

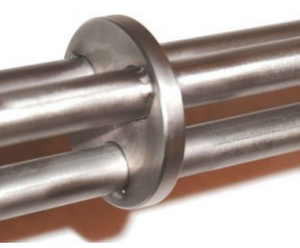

High pressure chemical injection quill, 1/2" to 1", SS316, PVC, Kynar, Hastelloy C276, Alloy 20, single

$ 133.00 $ 156.00

DESCRIPTION Standard injection quills are designed to ensure a more uniform and rapid dispersal of injected chemicals into the center stream of a process pipeline. This prevents corrosive liquids from...

Chemical injection quill with three chemical ports, 1"" to 2", SS316 with check and ball valve

$ 1,720.00

DESCRIPTION The Yamatho Triplex Injection Quill Type 316 Stainless Steel with check valve kit comes with the following: • System Connection size: 1" MNPT part number QT-316-100-CVK 1 1/2" MNPT part...

Optimizing Cooling Tower Performance: Understanding Efficiency, Maintenance, and Water Quality Management

by Aldo Zaffalon February 28, 2024 0 Comments

Revolutionizing Water Analysis: Everything You Need to Know About the Kemio KEM10DIS

by Aldo Zaffalon April 19, 2023 0 Comments