High pressure chemical injection quill, 1/2" to 1", SS316, PVC, Kynar, Hastelloy C276, Alloy 20, single

QC-316-050

2 reviews$ 133.00 $ 156.00

Standard injection quills are designed to ensure a more uniform and rapid dispersal of injected chemicals into the center stream of a process pipeline. This prevents corrosive liquids from clinging to the side of the pipe.

Injection quills are available in a variety of materials and pressure ranges. Pressure and temperature ranges are dependent on the material of construction and vary from 150 and 3000 psi and 100 °F (37 °C) and 750 °F (400 °C)

- Type 316 Stainless Steel, Alloy 20, and Hastelloy C276 quills are suitable for high pressure, high temperature applications.

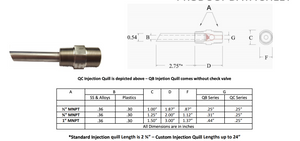

- Simple to use ½”, ¾”, or 1” MNPT male process connection and ½”, ¾”, or 1” MNPT male chemical inlet connection.

- The QC series of the Eddington injection quills come with a built-in check valve to prevent back flow of water or steam through the nozzle and into the chemical line.

- The crack pressure (amount of psi required to open the check valve) on the QC series of injection quills is 20 psi.

- For applications that do no require a check valve, the QB series of the Eddington injection quills come without a check valve.

- All of the Eddington injection quills come with two machined flat surfaces on external portion of nozzle so a wrench can be used during installation.

- The QC and QB injection quills come with the telltale V notch and witness mark to ensure proper nozzle alignment with process steam for proper dispersal of injected chemical.

- Standard quill length is 2 3/4″ long but custom lengths up to 24″ are available. For additional lengths please add the quill length desired to the end of the Eddington part number (e.g. QCFM-316-050-18).

- Made in the USA

- Available in larger sizes, up to 3” MNPT connection, contact us to request quote (sales@yamathosupply.com)

- Welded safety collar

- Also available CPVC, Alloy 20, Hastelloy C276, SS316

- Made in the USA

- Reviews

- Questions

Thank you for submitting a review!

Your input is very much appreciated. Share it with your friends so they can enjoy it too!

Injection quill does the work and it look very well made. Purchasing process was simple and delivery was fast. very happy

Great piece of equipment. One installation two chemicals. Great quality and responsiveness

Customer Reviews