Boiler blowdown, water TDS controller Lakewood Instruments model 1575e. Select add on options from dropdown list

1229239

1 review$ 1,544.00

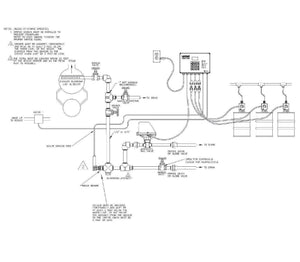

Boiler water TDS controller, designed to measure the hot boiler water conductivity (sensor SR2) and open or close a motorized ball valve, that will drain water from the boiler. The automatic control of water TDS allows the boiler to operate at safe levels of water concentration with the minimum amount of energy loses. Read article here for more details.

The sensor works up to 600 psi and 486 Deg F. Orifice plate needed to assure the integrity of the sensor. Below the available kits

- Part Number 1229239 is just the Model 1575e Controller only

- Part Number 1229244 is Automated Kit for 1/2" pipes - Includes 1575e Controller, SR2 Sensor, 1/2" Union, Orifice plate.

- Part Number 1229245 is Automated Kit for 1/2" pipes - Includes 1575e Controller, SR2 Sensor, 1/2" Union, Orifice plate.

- Part Number 1229243 is for Continuous Sampling - Includes 1575e Controller, SR2 Sensor, PLKT (The PLKT Plumbing Kit Includes 1/2" sample/cycle and continuous sample kit. Unions, Orifice plates, Cross, Tees, and Manual Block Valve Only. Does not include piping.)

Use code CCFTWZV2NJG3 for an instant 15% discount on checkout!

Lakewood Instruments boiler blowdown, conductivity controller 1575E , including controller, SR2 & PLKT plumbing. just add a motorized ball valve and you are good to go.

PLKT Plumbing kit. 1⁄2” sample/cycle and continuous sample kit

Includes unions, orifice plates, cross, tee, and manual block valve only

The Model 1575e uses the latest in microprocessor capability, giving the user a high level of application flexibility. A large illuminated graphics screen, multiple

inputs, and very easy setup characterize this new technology. The Model 1575e is ETL approved.

Watch this video to see the 1575e in operation! Click HERE

• Removable power cord and receptacles for simple conduit installations.

• Scheduled feed, which can use three relays for biocides or other chemicals.

• Two (2) water meter inputs, two (2) drum switch inputs, conductivity input, flow switch input, 4-20 mA output,

and remote conductivity input via 4-20 mA are all standard features.

• Designed with a single circuit board for better reliability and lower cost.

• Large open shallow enclosure for easy wiring.

• Ball valve delay feature allows accurate control of motorized ball valves.

• Heavy-duty stainless steel domed numeric keypad and illuminated graphical display allow for quick and easy

programming. Steel domed switches improve the tactile sensing and life expectancy of the keypad.

• LED indicators for power, alarm and relay status.

Easy to program with the Lakewood plain English, intuitive, and user friendly menu interface.

• Controller can be used in boiler, cooling tower, or condensate applications when used with the appropriate

conductivity sensor.

• Single circuit board design improves reliability.

• No add-on options. 4-20 mA output and feed schedule clock features are standard.

|

Conductivity range |

500-8000 µS for Boilers |

|

|

Conductivity sensor |

2 electrode |

|

|

Conductivity Resolution |

± 10 µS (conductivity <5000 µS) |

|

|

Temperature comp. |

± 100µS (conductivity <5000 µS) |

|

|

500NTC, NONE |

|

|

|

Accuracy & repeatability |

± 1.0% |

|

|

Deadband/Setpoint |

Programmable |

|

|

Auto/Manual outputs |

Menu selectable |

|

|

Keypad |

16 tactile push-buttons |

|

|

Display |

illuminated 128x64 pixel LCD |

|

|

Drum Switch Inputs |

2 digital contact inputs |

|

|

Water meter inputs (2) |

Contact head, paddle |

|

|

Timers |

wheel or turbine |

|

|

Max. blowdown time exceeded |

|

|

|

Output Signal |

and relay run time exceeded |

|

|

One 4 – 20 mA, isolated or |

|

|

|

|

non-isolated optionally powered |

|

|

|

output for conductivity |

|

|

Input Signal |

One 4-20 mA, non- isolated |

|

|

|

internally powered input for |

|

|

Output relays |

conductivity |

|

|

4, 3 selectable use, |

|

|

|

Relay ratings |

1 blowdown |

|

|

3A each, 10A total |

|

|

|

Power |

120/240 VAC 50/60 Hz |

|

|

Ambient |

32° - 120°F (0 - 49°C) |

|

|

Enclosure |

NEMA 4X, ETL |

|

|

Sensors/Plumbing |

Boiler |

|

Max Pressure |

600 psi (41.3 bar) |

|

Max Temp |

486°F (252°C) |

- Reviews

- Questions

Thank you for submitting a review!

Your input is very much appreciated. Share it with your friends so they can enjoy it too!

I have been suing these controllers for years. They are robust, easy to install and maintain. Other than replacing the ocasional part, they are rock solid. They do everything you need for a solid cooling water treatment.