Chemical injection quill for oil and gas application

January 20, 2021 0 Comments

Chemical injection quill for oil and gas application

To support users in their proper planning and technical evaluation, I would like to share some information about one less-familiar product in the industry, the chemical injection quill.

What is a chemical injection quill?

Chemical injection quill is a mechanical device used in the chemical injection process used across many industries. It is an interface equipment between the chemical feed line and the process pipeline. The injected chemicals are controlled to achieve chemical reaction while the quill helps to disperse this into the process pipeline.

Application fields

Chemical injection is used in many application such as injecting additives, chemical/bio treatment, and removal/separation process. To mention a few, below are examples of chemicals used in the oil/gas injection process:

Methanol

Used as hydrate inhibitors. Hydrate solidifies and can cause flow restriction or plugging in wells and flowlines.

Corrosion inhibitor

Used to mitigate the corrosion in wells and pipelines to reduce downtime.

H2S scavenger

Used to treat oil/gas in reducing H2S levels, to reduce health risk and corrosion.

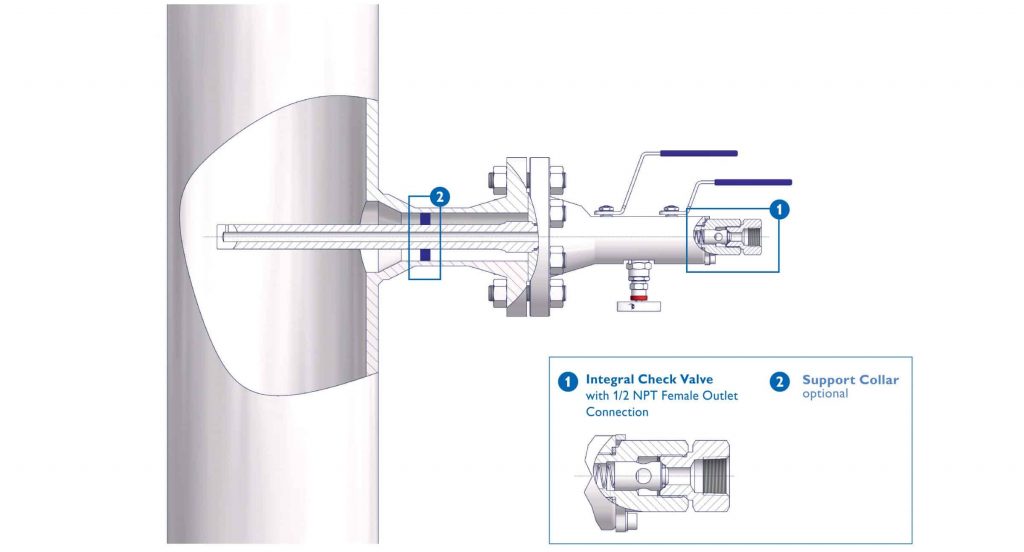

The injection quill could come in various configuration, connections and fittings: From a simple fabricated tube/probe to an integrated assembly with isolation valves and non-return valves. As part of our specialty, we manufacture an integrated chemical injection quill, complete with probe, double block & bleed assembly (2 isolation valves + 1 bleed valve) and an integral non-return check valve, all in one compact assembly. Looking at the illustration above, this injection quill can also be converted into a sampling quill by a redesign on the probe and without the integral check valve. Sampling quill is used to safely take out fluid samples from the process line for analytical or laboratory purpose.

This type of injection quill is mounted into the pipeline through a fitting in such a way that the quill/probe is inserted and extends down to the center of the process line. The other end is connected to the chemical feed line by pipe or tubing connections all the way back to the chemical injection skid or chemical Dosing packages that house the pump and chemical tank.

Designing an injection quill

When designing an injection quill following points must be considered:

Design calculation

The wake frequency calculation is based on standard ASME PTC 19.3 TW-2010 for Thermowell since the quill is very similar to it. Since the design requires both thermal and stress considerations, the customer should provide the necessary process data (fluid, temperature, pressure, velocity, flow rate, density, viscosity). If the calculation is not satisfactory, a support collar can also be used to achieve a good result. A poorly designed quill can cause early failures and replacement.

Material

Material grade should be suitable to the service as well as suitability to the type of chemical to be injected. Since the quill is an integrated assembly together with the DBB and check valve, several parameters need to be evaluated as you would do for an isolation valves. This includes the valve body and trim material, whether soft-seat or metal-seat, etc.! Many mechanical failures are our caused by poor selection of material grade.

Safe isolation

There are quill designs without integral isolation valve or involving only single isolation. To upgrade the safety level, an integral DBB valve is important in certain applications and media. Such is the case for Injection Quill installed in very high pressure API 6A wellheads where pressure is rated at 10,000 psi. Talking about safety, the sealing design and leakage rates of the valve are critical. We have a regular customer for injection quill where they require mandatory API PSL 3G PR2 because of very sour gas service. This testing and quality criterion is very special not all manufacturers can achieve.

Dimension

One of the most important parameter in the wake frequency calculation is the length of the quill. The length is usually customized or as specified. In general, the injected chemical is dispersed well if the nozzles are positioned at the center of the pipeline.

Nozzles

The standard for the injection quill is the usual cylindrical tubes or nozzles. However, other applications or users require special designed nozzles for better atomization.

Mounting options

There are different mounting options. To some design, it could be flanged, welded or threaded, but we must make sure that the quill/probe outside diameter (O.D.) will fit all the way down to the process stream. In one experience, the quill/probe outside diameter (O.D.) do not fit because of the welding penetration takes the small tolerances. Also for very high pressure, threaded connection is generally not preferred.

Also in Blog

Advanced Cooling Tower Management: Enhancing Efficiency with Lakewood Model 140

February 28, 2024 0 Comments

Optimizing Cooling Tower Performance: Understanding Efficiency, Maintenance, and Water Quality Management

February 28, 2024 0 Comments

Revolutionizing Water Analysis: Everything You Need to Know About the Kemio KEM10DIS

April 19, 2023 0 Comments