Cooling conductivity control basics

December 14, 2015 0 Comments

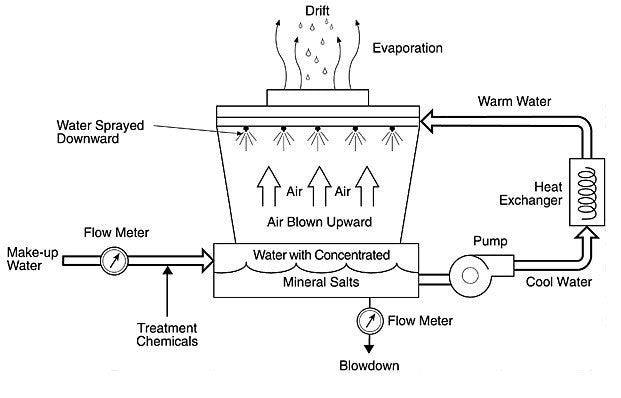

Easy to implement and maintain, conductivity is the most cost effective way to automatically control de concentration cycles in a cooling tower. Well-developed sensor technology, slow response process and a electric valve in the blowdown line, and you are all set. At least if the application is straight forward.

Many things could affect the effectiveness of the control system, including equipment failures, process changes and process failures. Let’s talk a bit about the issues that could cause:

Conductivity always too low: in this case the water inside the cooling tower is not concentrating, or at least not concentrating enough. As a result, the customer is spending more money in treatment and water than they should. What could cause this situation? Let’s think about it for a minute, if the cooling tower is operating and water is evaporated, then the conductivity should be steadily increasing, and there are only two reasons for it not to be happening; water is leaking from the cooling system or, clean water is entering the cooling system. That is it, no other explanations.

If there is a source of clean water entering the cooling system, the conductivity will stay low, even if the blowdown control is not bleeding and the makeup water is not entering the system. Granted, the cooling tower level should steadily go up but, if the water is clean enough, it could basically just replace evaporation, keeping the conductivity low and the level steady.

If the system is bleeding because of an uncontrolled leak, then the makeup water will flow in, to replace the lost and the control system may never have to operate the blowdown valve. In this scenario a source of leakage could also be the blowdown valve.

Conductivity always too high: This is the opposite and most common scenario. In this case the conductivity is always higher than the maximum value required for the cooling system. It can cause serious damage to the cooling and process systems. When you look at the way the cooling tower operates, there are only few changes in the system that can create this issue.

The most common one is the blowdown valve. If the valve is too small or, if it is clogged, then the cooling system is not bleeding enough water and the conductivity is always high. On the other hand, a contamination from the process or, contaminated water entering the system, could create a situation in which the blowdown valve will never be able to bleed enough water. In this case the valve will always be open.

To troubleshoot a cooling system with problems, all you have to do is go back to basics, verify that the control equipment works (easy) and, if that does not work, start looking for changes in the cooling system and process.

Signup to receive our newsletters, articles and special offers!

Also in Blog

Advanced Cooling Tower Management: Enhancing Efficiency with Lakewood Model 140

February 28, 2024 0 Comments

Optimizing Cooling Tower Performance: Understanding Efficiency, Maintenance, and Water Quality Management

February 28, 2024 0 Comments

Revolutionizing Water Analysis: Everything You Need to Know About the Kemio KEM10DIS

April 19, 2023 0 Comments